A stretch ceiling is one of the most interesting forms of interior finishing. It is an interesting alternative to the standard ceiling or, for example, coffers often used in offices. In a situation where the stretch ceiling can be freely finished in terms of graphic – and therefore color-matched to the interior – has become a particularly interesting option for people looking for original solutions.

What is stretch ceiling?

A stretch ceiling is a flexible material made of a special foil. It is located on a structure prepared for the right dimensions. Before installing, the material needs to be heated to achieve perfect tension. A smooth surface is then created, with an aesthetics finishing.

Installation of a stretch ceiling is also its advantage. Contrary to similar solutions – drywall ceilings – the installation of a stretch ceiling is much faster and cleaner.

The stretch ceiling, thanks to the material from which it is made, also has very valuable technical features. On the one hand, it allows free arrangement of the interior. Nothing stands in the way of giving it an appropriate color scheme that will be ideally suited to the rest of the office or room interior. On the other hand, PVC foil used as a base material for stretch ceilings is waterproof. This reduces the risk of moisture penetration.

How stretch ceilings are made?

In the production of stretch ceilings, the quality of the material used, the perfect cut of the material and the strength of the welds are extremely important. This is due to the way stretch ceilings are mounted. The base material – before stretching – is cut out, and then, in the case of large surfaces, the sheets of foil are welded together. In the next stage of production, a harpoon is welded to them. For these realizations, the SUPRA high-frequency welding machine were created.

The SUPRA MAX HF welding machine was developed for the production of stretch ceilings. Small size, is more adaptable to the current machine park. However, it is worth remembering that the machine can be equipped with additional tables designed for easier welding of larger elements.

For every machine Zemat Technology Group offers tooling (electrodes), thanks to which a high-quality, durable and aesthetically perfect welds can be created, which are practically invisible from short distance.

What is important, machines for the production of stretch ceilings are characterized by high versatility of use. They can be used both for welding PVC foil and very important in this technology overheating harpoons necessary for tensioning ceilings.

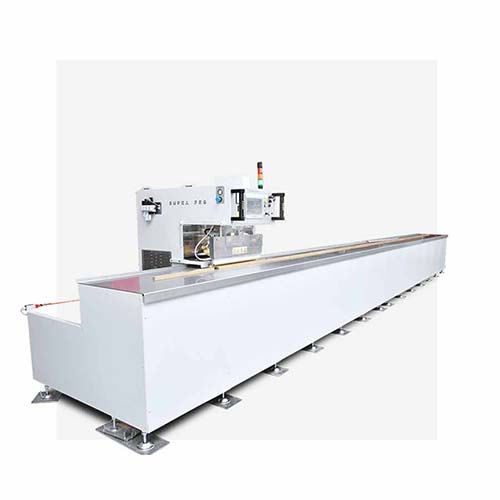

The most advanced machine is the traveling SUPRA PRO welding machine. A long work table that can be equipped with a vacuum or laser guides allows for comfortable work even with long elements. It also has a significant impact on the precision and the speed of production of the stretch ceilings. The HF head moves along the working table using special rails. This ensures smoother movement and precise distance control.

Not only the production of stretch ceilings

The versatility of SUPRA HF welding machines allow them to be used also in other applications. These features are important if a manufacturer wants to use them also for other non-standard orders.

The large surface of the working table, easy replaceable tooling, a system of smooth adjustment of the input power and adjustable pressure give great possibilities to use SUPRA machines in other applications. Apart from stretch ceilings, SUPRA is used in the production of interior decorative materials, stretch exterior decorations in 3D format and various advertising materials.