Characteristics of ROLLMAT roller die cutters

ROLLMAT roller die cutting machines find successful application in industry, where precise cutting of various materials is required. Through the use of advanced technology, these machines can generate pressures of up to 150 tons, which allows both thin and thick layers of materials of varying hardness to be processed efficiently.

One of the key elements of the ROLLMAT roller die cutting machines consists of a control panel working together with a PLC, enabling the machine’s operation to be flexibly adapted to the user’s needs. This control system enables both manual and automatic operation, thus providing the machines with the versatility to be used in a variety of production processes.

Also of note are the machine shafts, covered with a special polymer. Most importantly, such a solution enables economical regeneration of the punch shafts and prevents rapid degradation of the punch knives, significantly reducing the long-term operating costs of the machine. In addition, the operation of ROLLMAT roller die cutting machines is smooth, translating into operator comfort and lower energy consumption.

Safety and reliability are other essential features of ROLLMAT roller punching machines. The machines are manufactured in accordance with international ISO standards and bear the CE mark, which guarantees their high quality and durability. Achieving ISO certification provides us with a certificate that allows us to be perceived as the most reliable and professional company in our field of activity. On the other hand, the CE marking is confirmation that the machines we produce comply with the European Union requirements specified for them, and are therefore internationally traded goods.

ROLLMAT roller die cutters are irreplaceable in many industries where the precision die cutting of materials is required. Among other applications, they are used for die cutting hard and soft foils, cardboard, paper, leather, and plastics. Furthermore, with their creasing and perforation capabilities, these machines are perfectly suited for packaging production. Consequently, ROLLMAT roller die cutting machines represent an invaluable tool for many companies across a wide range of industrial sectors.

Applications of ROLLMAT roller die cutters

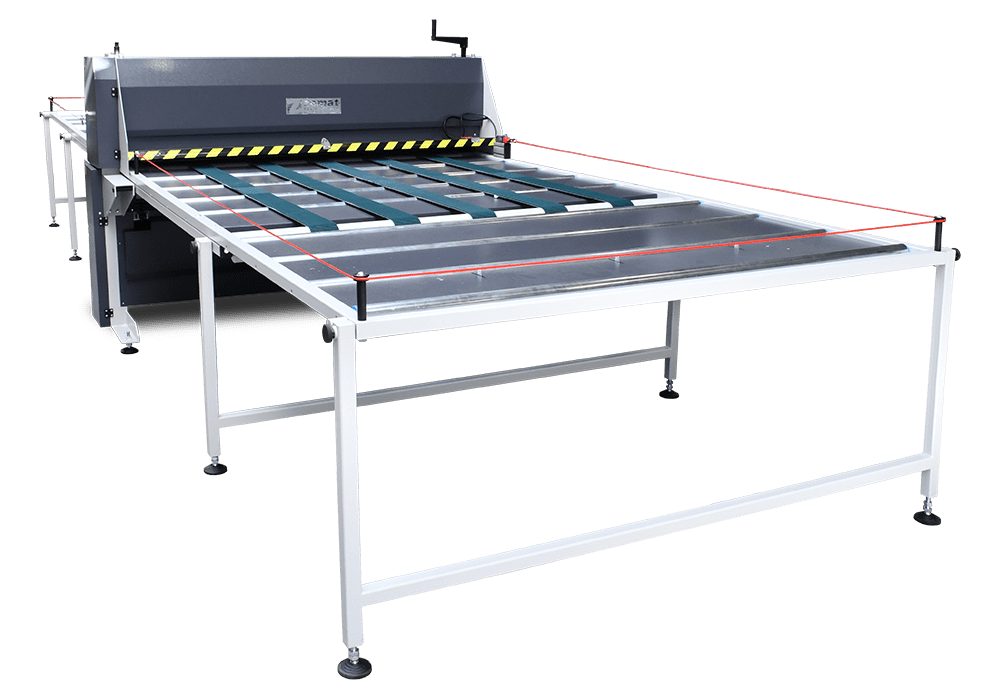

ROLLMAT roller de cutters are extremely versatile. They are perfect for the production of short runs, with easy operation requiring no special skills. Usable widths of the machines range from 800 mm to 2500 mm, enabling a wide variety of tasks to be carried out. Working efficiency is 20-30 cycles per minute, ensuring speed and efficiency in production.

ROLLMAT rollerdie cutting machines are utilised in many fields. They are employed to cut corrugated cardboard up to 13 mm thick, using either 2, 3 or 5 layers. They can also be applied to cut fibreboard up to 5 mm, subject to the density of the material. These die cutter machines make perfect machines for working with polymers such as hard foils, PVC, PP, PET, PE, HDPE, thermoformable foils. These are also utilised for the production of packaging, like inserts, boxes, as well as office supplies.

ROLLMAT roller die cutting machines are also excellent when working with foam of different thicknesses and densities. They may be used for cutting leather and leather-like materials. These are also employed to cut technical nonwovens. With the ability to quickly change dies and cut different material thicknesses from 0 to 13 mm, these machines are extremely versatile and practical.