- Industries

- MachinesWelding and sealing machinesPopular industrial machinesOther industrial machines

- TechnologyWelding technologiesOther technologies

- SupportSupportMore Services

- CompanyCompany Zemat Technology GroupEU Projects

- BLOG

- ContactContact with Us

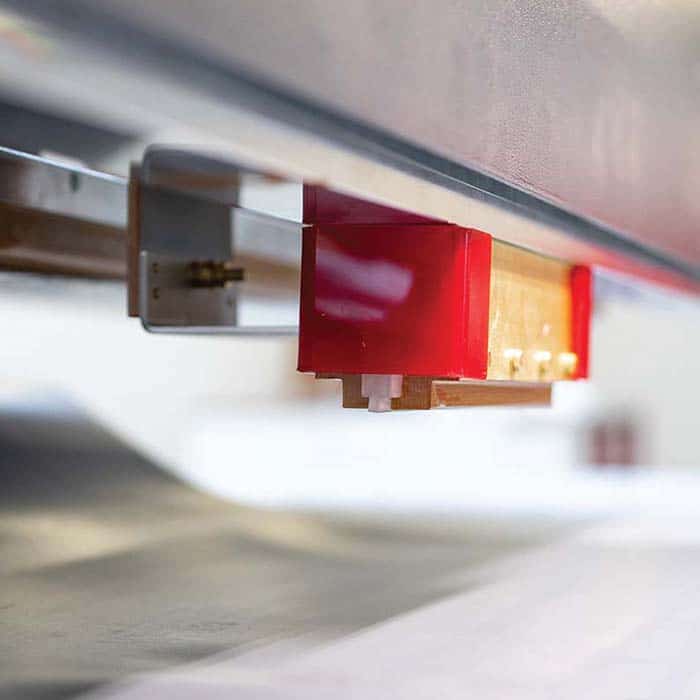

FreeWeld™ System

- Home

- Technologies

- FreeWeld™ System