SUPRA MAX high frequency welder is designed specifically for use in production of Stretch Ceiling (French Ceiling) interior design elements. The machine is equipped with special high grade welding/cutting electrode to achieve perfect straight line “invisible” seam.

Thanks to the high precision of work, it is possible to obtain rectilinear, aesthetic and very durable welds.

SUPRA high frequency welder has universal application for both: PVC film welding and Harpoon welding with the use of special patented IAW™ Inverted Airplane Wing shape tooling. Cork coated work table allows handling of very thin and delicate films and backlit weld area helps to visually inspect weld precision and quality.

Pneumatically driven welding bar is moved up & down with the use of foot switches allowing the operator both to use both hands for exact material positioning under the electrode, while ZTG SafeDOWN™ anti-crush safety system and pneumatic lock down front gate assures the safe work environment.

The machine can be upgraded (if needed) with additional length work tables for easier film and harpoon positioning during the weld cycle. It can be converted easily into an advertising banner/billboard welder with the use of special wide weld electrode or any other straight bar or spot HF welder.

Full diagnostic testing and certification of the local factory EMC/EMS parameters according to the latest guidelines required by the CE & UL standards. We have our own ISO 17025 certified production control and EMC laboratory providing validation of each required process parameters and the whole technological production cycle.

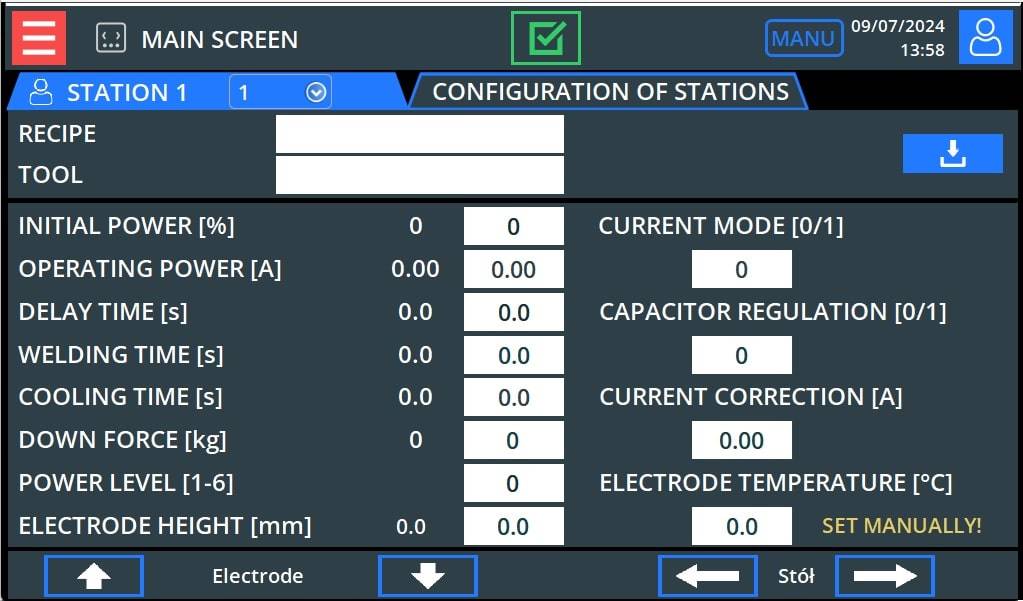

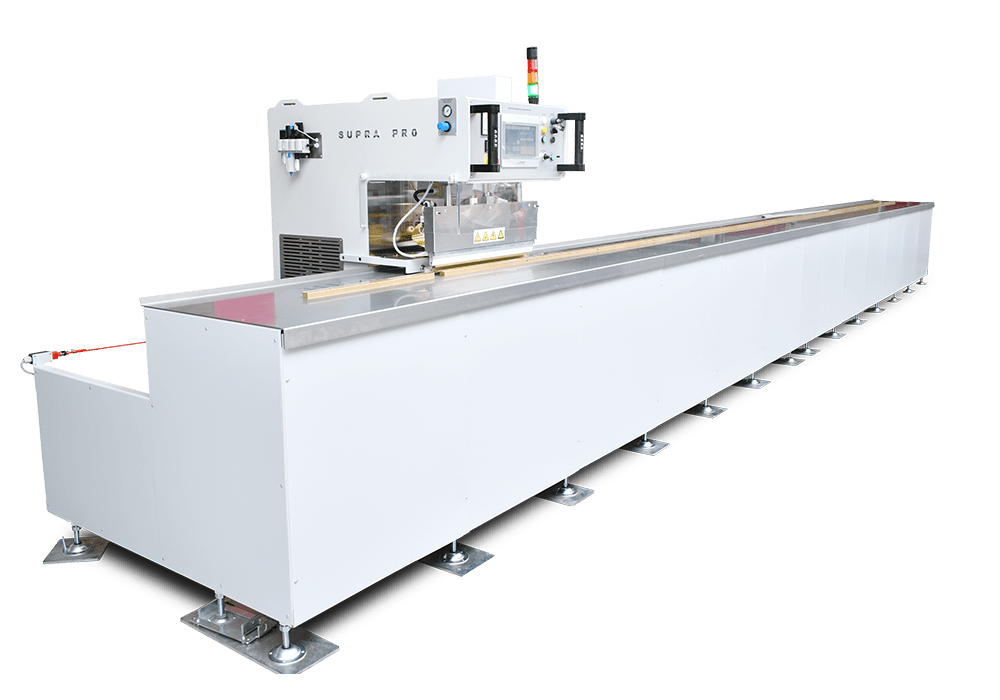

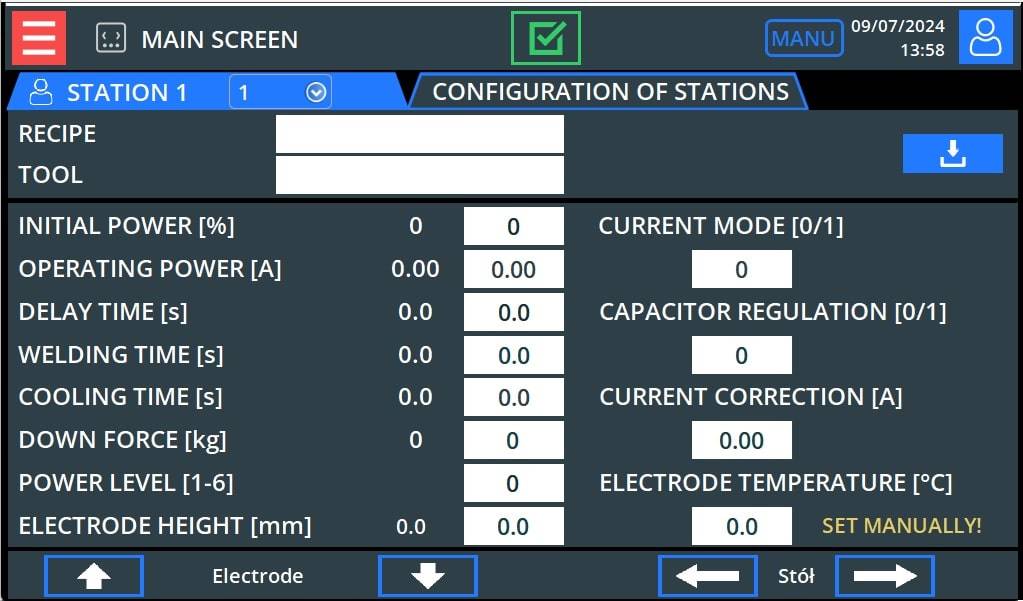

Traveling Head SUPRA PRO high frequency welder was developed specifically for production of large format Stretch Ceiling (French Ceiling) interior design elements. The machine is equipped with special high precision linear motion gear controlled by frequency inverter to achieve a perfect continuous weld “invisible seam” weld.

SUPRA high frequency welder has universal application for both: PVC film welding and Harpoon welding with the use of special patented IAW™ Inverted Airplane Wing shape tooling. Cork coated work table allows handling of very thin and delicate films and backlit weld area helps to visually inspect weld precision and quality.

Pneumatically driven welding bar is moved up & down with the use of foot switches allowing the operator both to use both hands for exact material positioning under the electrode, while ZTG SafeDOWN™ anti-crush safety system and pneumatic lock down front gate assures the safe work environment.

The machine can be upgraded (if needed) with additional length work tables for easier film and harpoon positioning during the weld cycle. It can be converted easily into an advertising banner/billboard welder with the use of special wide weld electrode or any other straight bar or spot HF welder.

Full diagnostic testing and certification of the local factory EMC/EMS parameters according to the latest guidelines required by the CE & UL standards. We have our own ISO 17025 certified production control and EMC laboratory providing validation of each required process parameters and the whole technological production cycle.

ZEMAT TG High Frequency welding machines are designed and built to very strict European Environmental and Safety regulations and have custom design solutions for weld and safety control.

ECO-Friendly HF Technology incorporated in the High Frequency machines contains:

| Energy efficient ECO HF generators with microprocessor control of output power

| Low power consumption and real time power output recognition

| 90% less power consumption than with traditional heat powered welding systems

| Dynamic High-performance HF impedance matching

| Dynamic Auto Tuning and Arc protection unit

| Ultra-fast reflected power control

| RF power output efficiency at 70-90%

| Harmonic distortions eliminated by frequency band filters

| Very limited heat dissipation preventing overheating

Get in touch

Zemat Technology Group Sp. z o.o.

ul. Brukowa 26

91-341 Lodz, POLAND

Phone: +48 42 632 84 84

Fax: +48 42 299 60 46

What we do