Universal use

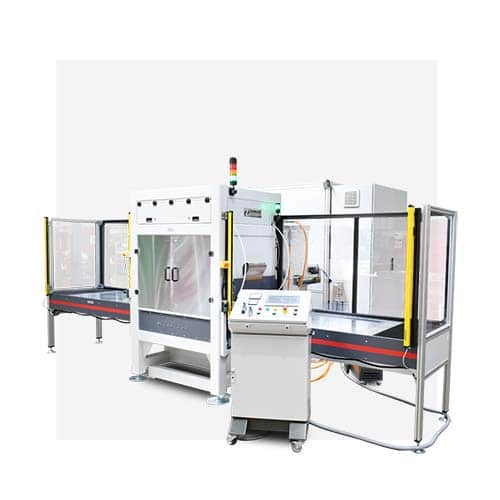

SIGNA or SIGNA DUO with automatic, pneumatically driven work trays are perfect machines for serial production of blister & clamshell packages, medical containers like blood or ostomy bags, laboratory, rehabilitation equipment, automotive parts and assemblies, cosmetics, etc. Heated electrode plate with temperature presets gives high accuracy for consistent welding of hard PVC/PET foils or PU foams.

The high frequency welder can be easily converted to a standard Heat Sealer for applications where HF welding is not necessary or impossible (e.g. PP or PE materials). The machine is equipped with quick change four point electrode holder. Custom built tooling and electrodes are available upon request. We have our own in-house tooling department which will design and make any electrode and die required for any demanding production needs.

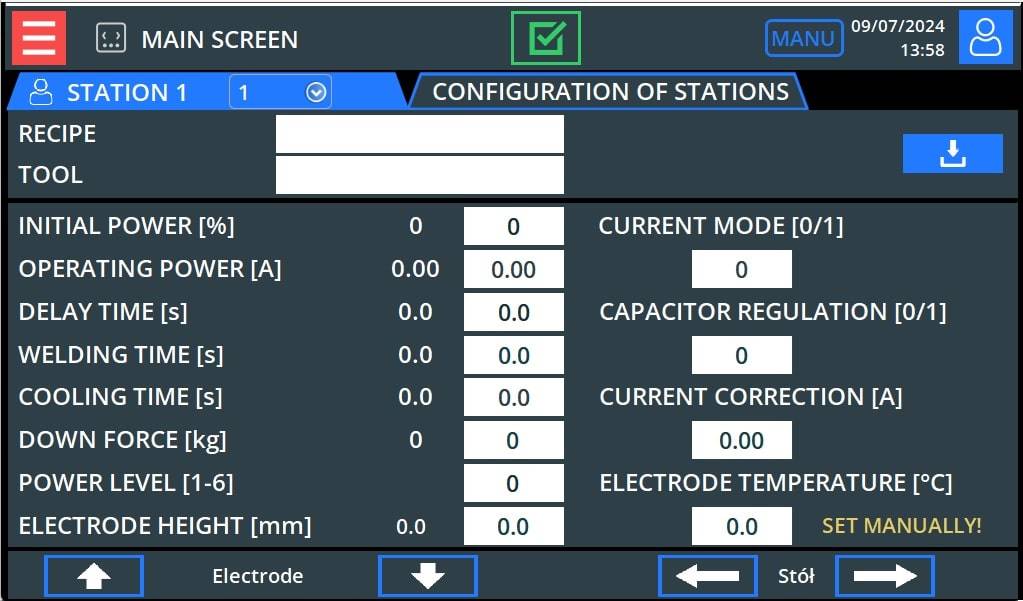

With the use of 10″ touch screen HMI and programmable PLC, operator can easily save hundreds of weld/seam recipes and upload or download them to/from USB drive. Full advanced programming functionality, including ATSTM Autotuning, WCSTM Weld Control Systems and VPN client provide excellent flexibility for demanding and advanced industrial environment. All available options, settings and safety features make this machine a perfect tool for high-end production where precision, durability and strength is the key.