Universal welding machine

SIGNA 4 is a perfect machine for production of blister & clamshell packages, medical containers like blood or ostomy bags with switchable welds for tubes and outer edge, laboratory, rehabilitation equipment, automotive parts, cosmetics, etc. Heated electrode plate with temperature presets gives high accuracy for consistent welding of hard PVC/PET foils or PU foams.

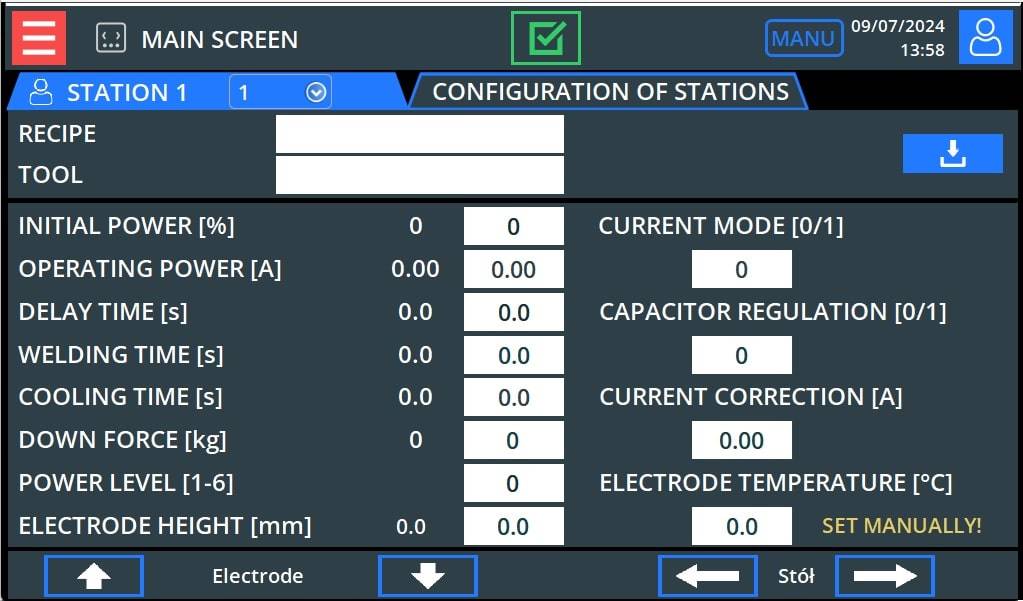

The high frequency welder can be easily converted to a standard Heat Sealer for applications where high frequency welding is not necessary or impossible (e.g. PP or PE materials). The machine is equipped with special quick change electrode holder. Custom-built tooling and electrodes are available upon request. We have our own in-house tooling department which will design and make any electrode and die required for any demanding production needs. With the use of touch screen HMI and programmable PLC, the operator can easily save multiple (1000) weld/seam recipes.

All available options, settings and safety features make this machine a perfect tool for high-end production where precision, durability and strength is the key.