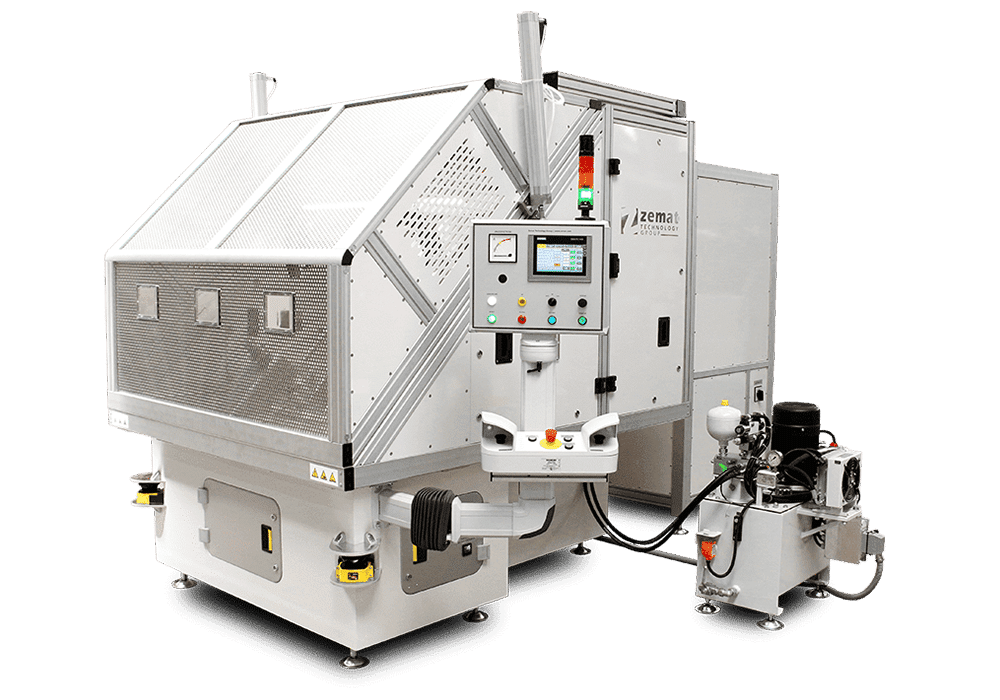

High frequency drying

PRESA equipped with customized forming/shaping tools enable production of yoke collars and corner collars for inner and outer circumference shapes. The customized press table with dimensions of 1300 mm x 800 mm allows production of a wide range of collars; especially large collars according to your drawings.

Thanks to this machine, we may dry and form collars from variety kinds of preshpan (wet and dry preshpan LD or HD) within the range from 0,5 to 5 mm thickness. In the process of drying we use antithetic energy of electric field with frequency of 27,12 MHz. Preshpan is heated steadily in all volume to the temperature of boiling. In this process we have an effect of dielectric loss of water from preshpan. In dependence of preshpan thickness, drying and obtaining final product may take something about 15 minutes.

Thanks to aluminium forms we may get collars with radius in the range starting from R300 to R2000. There are two kinds of collars we may produce: external (outners) and internal (inners).