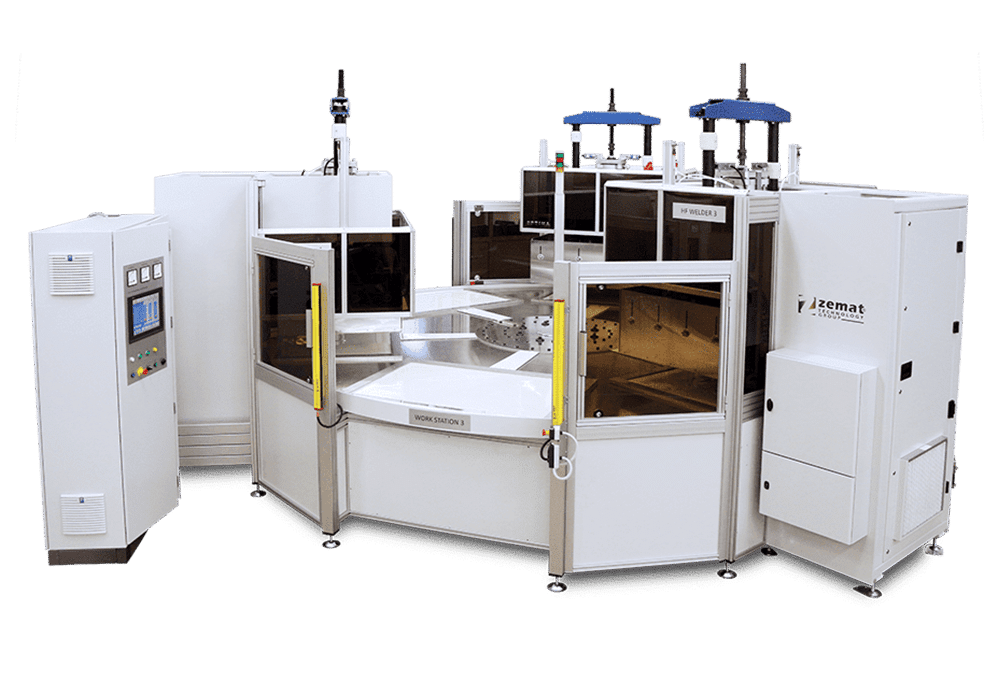

Unique design

OPTIMA high frequency welder worktable is equipped with special high-precision rotary indexing gear controlled by frequency inverter. The machine operation is based on step by step technology with possibility of multiple welds in one cycle.

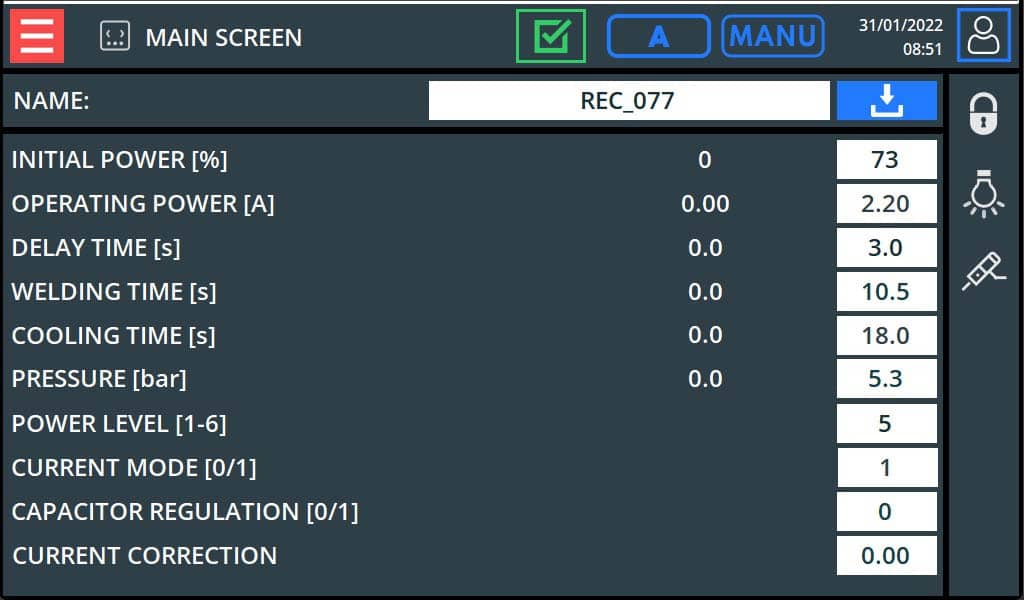

With the use of touch screen HMI and programmable PLC, the operator can easily input multiple weld/seam recipes. OPTIMA series machines have production power outputs from 10kW to 20kW for multi-cavity production loads and specialized products.

Automatic weld cycles, optional preheated or cooled weld platen, pneumatic or hydraulic weld head drive, electronic motion and weld cycle counter make this machine a perfect tool for a high-end production facility where precision, durability and strength are the key.