High-quality seals

Mega is a perfect machine for production of laminated PU foam embossing, car/truck door panels and tops, automotive and airline carpeting and seat covers, car trunk floors and covers, as well as medical, laboratory, rehabilitation equipment, safety vests, reflective signs, etc. Optional heated electrode platen with temperature presets gives high accuracy for consistent welding.

The machine is equipped with special quick change electrode holder. Custom-built tooling and electrodes are available upon request. We have our own in-house tooling department which will design and make any electrode and die required for any demanding production needs.

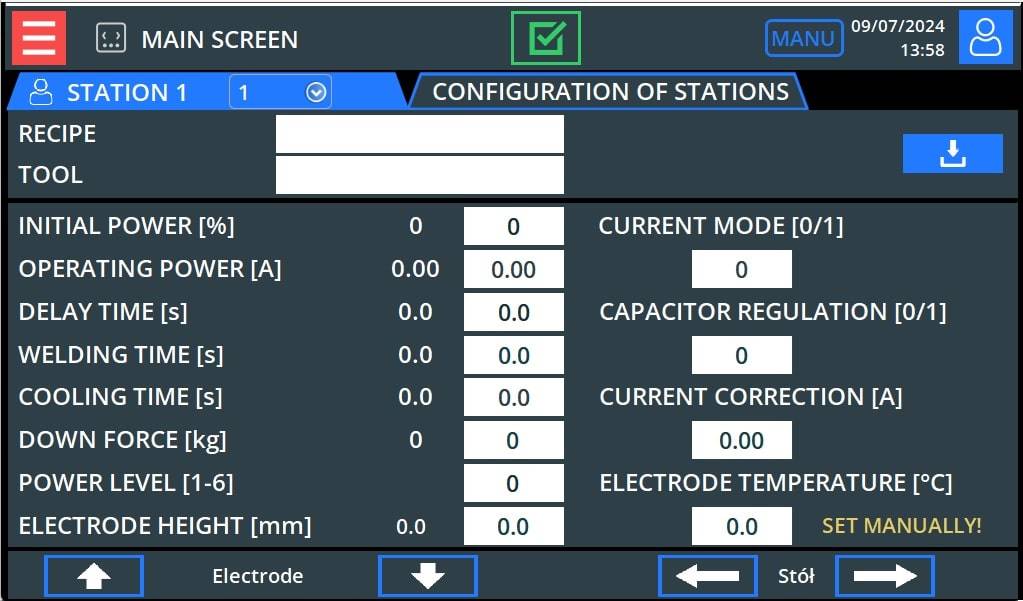

With the use of touch screen HMI and programmable PLC, the operator can easily input multiple weld/seam recipes. MEGA series have HF power outputs from 15kW to 30kW for heavy production loads and special projects using reinforced heavy-duty materials. All these options make this machine a perfect tool for high-end production where precision, durability and strength is the key.