Any shape of the electrodes

The tooling (electrodes) in the CORNA high frequency welder for complex shapes can have custom shapes – rectangular, round, triangular or oval – depending on the final product look. FlexEL flexible electrode can be also used for changeable layers welds (e.g. going from 2 layer weld to 8 layer weld and coming back to 2 layer weld again). Connecting 3D corners can be achieved easily with the column design of the welding head and footing.

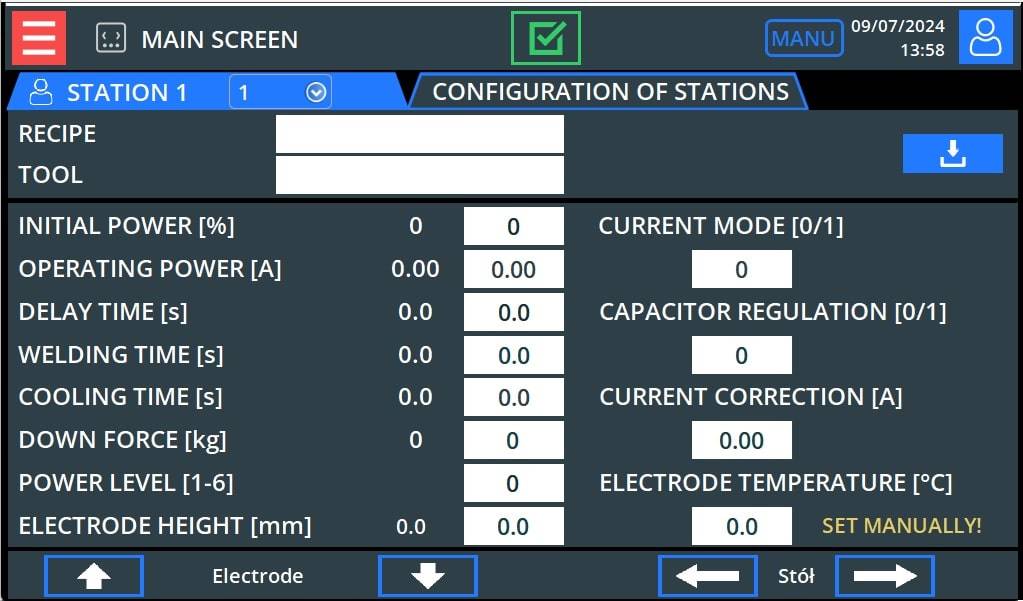

Operation is easy and intuitive. The machine is equipped with freestanding control panel and HMI touch screen. It can also be put on wheels for ease of movement and placing in a desired, for the comfort of production, place.

New generation Hi-Q3 reliable HF generator with 4kW of output power provides consistent welds and minimum RF exposure for operator. Machine is made to CE regulations and tested according to ISO17025.