Universal HF welding machine for conveyor belts

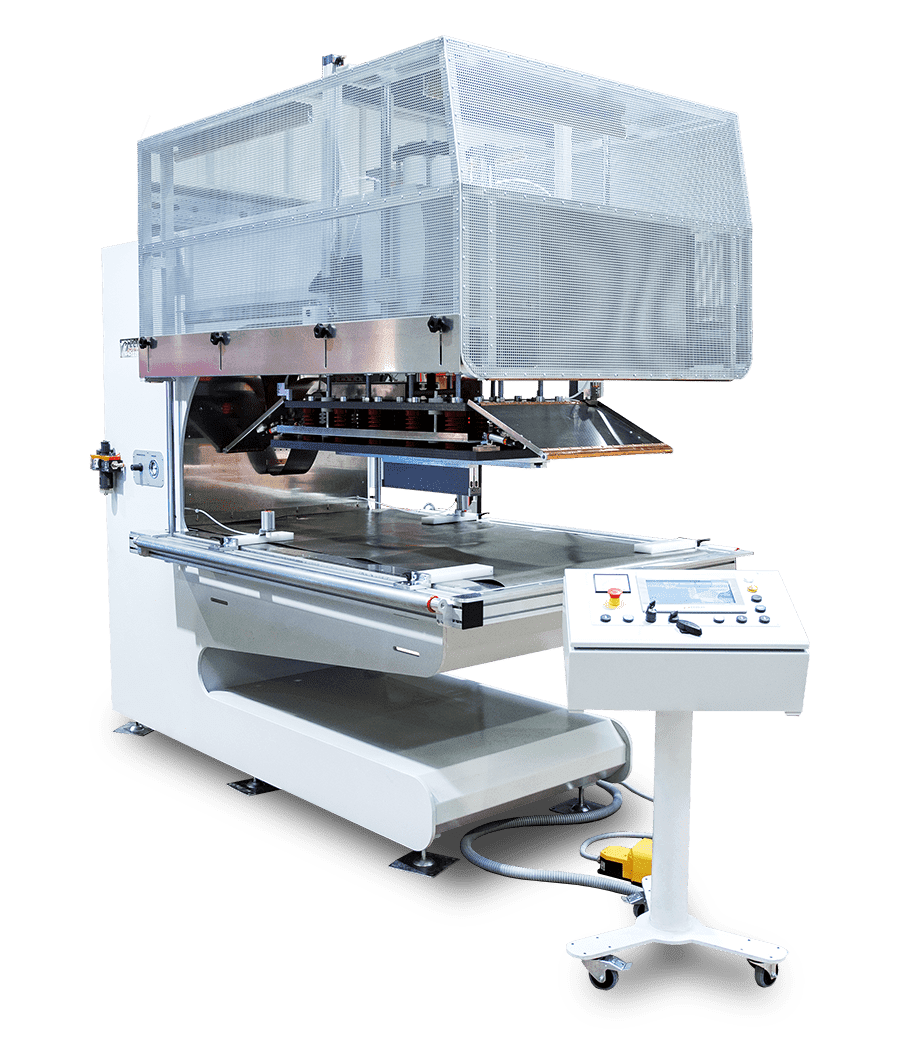

With the BELTA machine the durable joining of all components is made easier thanks to, among other things, its large work table size and the work plate, to which the electrode can be attachedat virtually any angle (even up to 360°).

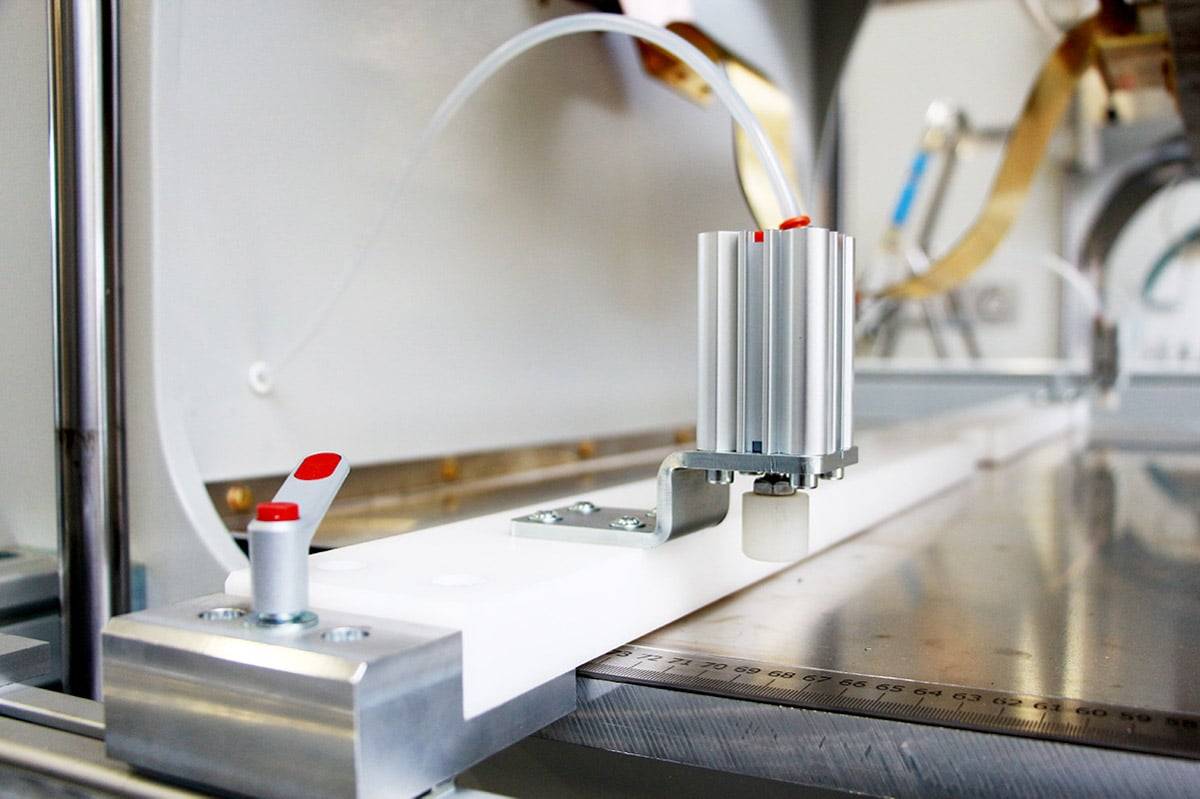

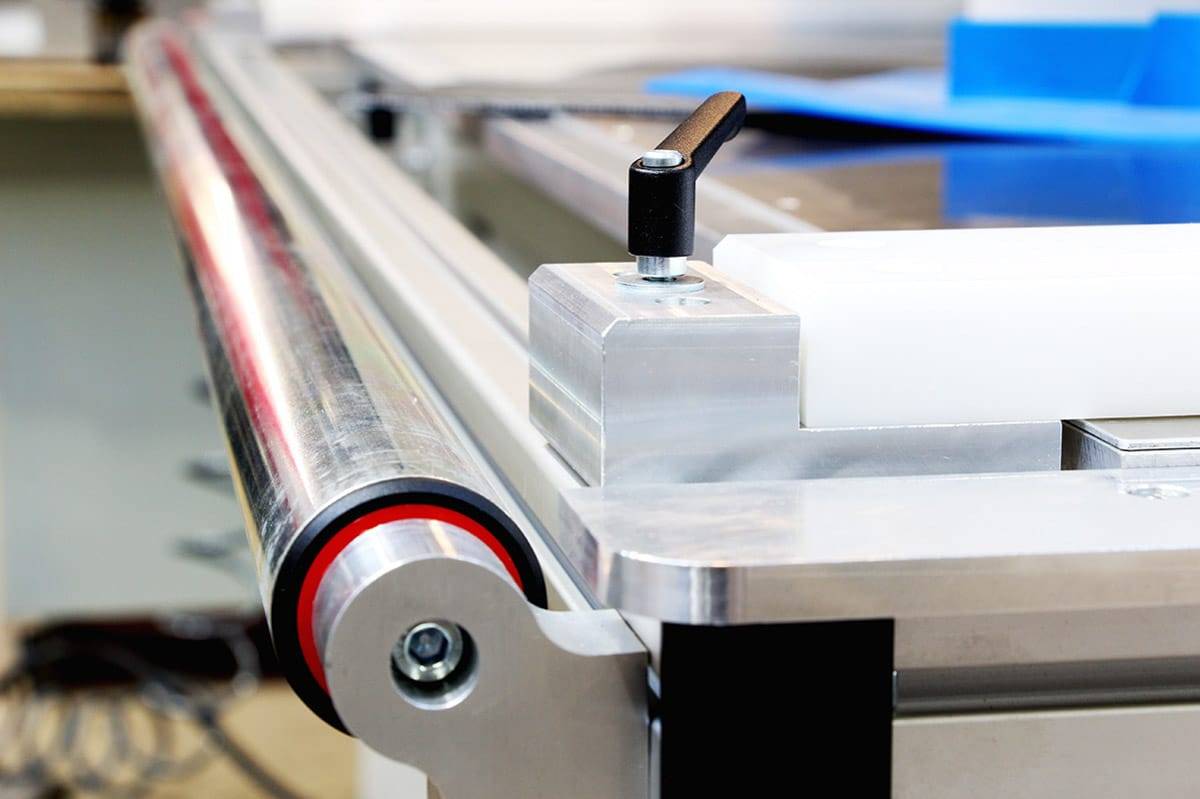

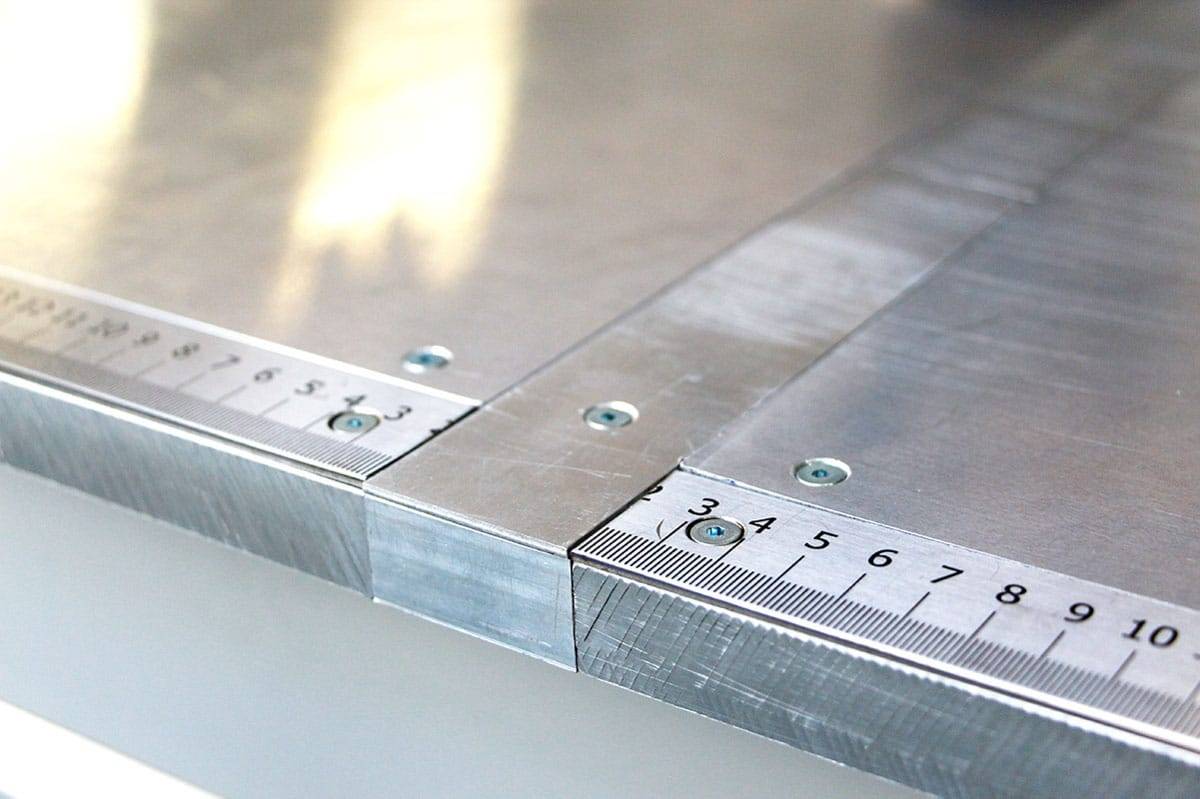

The BELTA conveyor belt welder is equipped with a special quick electrode change system. With the track rollers that are installed on the edges of the work table, it is easier to slide and position long and heavy conveyor belts, making the operator’s work time-efficient and ergonomic.

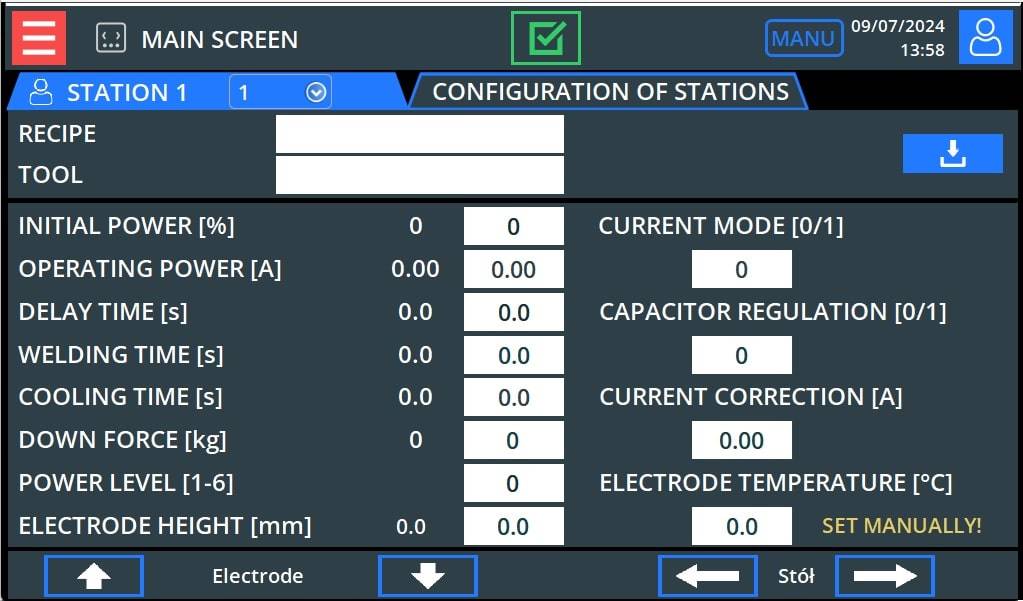

Through the use of modern touchscreen (HMI) and a PLC, the operator is able to easily set the welding parameters and store more than 1,000 programmes in memory in order to work on different types of materials and electrodes. BELTA series HF welders are typically manufactured at an output power of 6 to 20 kW, suitable for welding materials of different weights with cleats ranging from 10 to 150 mm in height. Theadvancedsafety systems and operator support modules employed on this machine also help make it the ideal tool for manufacturing products with quality and aesthetics as a priority.

Specialising in the conveyor belt production

Zemat Technology Group is a well-established manufacturer of conveyor belt production machines. Our product range consists of a wide range of machines which are vital for the production of high-quality conveyor belts. Our belt welders are used for the production of belts made of various materials such as PVC, TPU and PU. We also offer specialised tooling aimed at the rapid weldingof PVC and PUcleats to the conveyor belts.

Our machines are equipped with modern control systems which enable precise setting of the welding parameters. As a result, the entrepreneurs whom we equip with these types of industrial machines obtain an industrial machine that ensures that components for conveyor belts, cleats, sidewalls or profiles are joined together in a consistent, high quality.

Good quality conveyor belts in particular are characterised by: high durability and abrasion resistance. It is equally important that they are flexible and resistant to a variety of external influences, including temperature, humidity and UV radiation. Furthermore, conveyor belts should not only be easy to install and maintain, but also cost-effective to run.

Key machines for conveyor belt production

There is a variety of machine types utilised in the conveyor belt production. Among the most important of these are high-frequency welders.

Good quality conveyor belt machines should be primarily distinguished by their high operating precision, reliability and durability. It is also essential for them to be intuitive to use and easy to maintain, thus also improving the execution of production processes. Our machines satisfy all of these requirements. They are fitted with modern control systems which enable precise setting of the working parameters. With their reliable operation, these machines are also capable of producing belts in series with a reproducible high weld quality. Furthermore, we provide a full range of technical support to our customers, encompassing machine training and service.