Easy action through foot pedal

DEPTA NX is a universal, high frequency welding machine and can be used in various industries. For seaming type work, a small tool mount is recommended to give good visibility and access to the work area. For other applications a large mount can be supplied giving rigid support over a wide tool area. Facilities are also available to increase the throat space, where excess materials have to be positioned behind the tooling.

DEPTA NX is widely used in medical, automotive and clothing industries for welding small add-on parts, like tubing, air and fluid valves, hooks, grommets, plates, etc. DEPTA NXhave a high frequency power output from 0.5 to 4kW. The machine is a perfect tool for auxiliary production where precision, manual approach, durability and strength are the keys.

FootDown™ System

- Lowering of the weld die/electrode platen by operator is done with equal press force foot pedal.

- Welding cycle and weld/seal pressing is executed with pneumatic cylinder for even and controlled pressure.

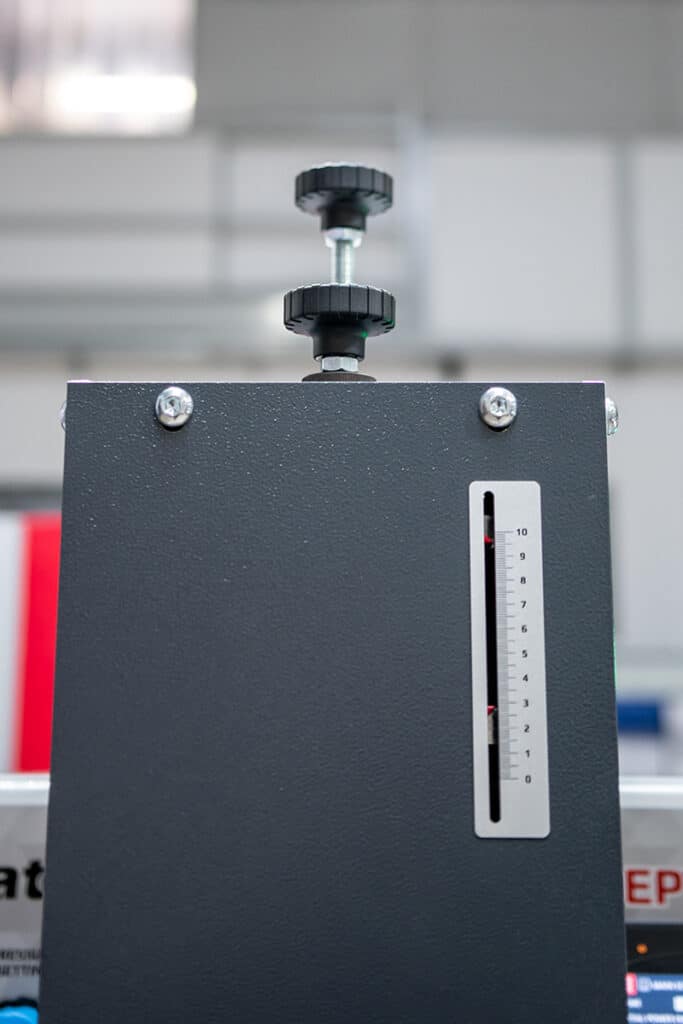

StrokeDOWN™ System

- Precision manual crank-knob system for quick and easy setup of height adjustment of welding electrode from the work table. Very useful for welding very thin films where seam thickness must be uniform and precise.