Powierzchnia stołu z nierdzewnej stali magnetycznej

Składany stół

Panel sterowanie na ruchomym ramieniu

Sterowanie elektrodą za pomocą joysticka

Duża przestrzeń za elektrodą

Wygodna obsługa za pomocą przełącznika nożnego

Elektrody o długości do 1200 mm

Projektory laserowe do pozycjonowania materiału

Przestrzeń robocza podświetlana diodami LED

Kółka umożliwiające łatwe przemieszczanie maszyny

Uniwersalna zgrzewarka wysokiej częstotliwości SIMPLA została zaprojektowana do produkcji małych i średnio gabarytowych produktów takich jak: struktury napinane, namioty, plandeki, wykładziny basenowe, bramy szybkobieżne.

Wieloletnie doświadczenie w produkcji zgrzewarek wysokich częstotliwości sprawia, że SIMPLA to idealne rozwiązanie pozwalające na ciągłą, bezproblemową i wydajną pracę, w której jakość i precyzja są priorytetem.

Maszyna wyposażona jest w wydajny i oszczędny generator o mocy 10 lub 15 kW, co pozwala na zgrzewanie ciężkich materiałów plandekowych oraz membranowych i wykonanie zgrzewu o powierzchni do 800 cm² materiału w jednym cyklu.

Standardowe wyposażenie obejmuje elektrody liniowe o długości do 1200 mm, funkcjonalność urządzenia można znacząco zwiększyć poprzez zastosowanie dodatkowych rodzajów elektrod: elektrody segmentowe FLEXel™ (łączenie różnej ilości warstw w jednym cyklu), elektrody łukowe (łączenie elementów do konstrukcji 3D i produktów kształtowych) i elektrody impulsowe (łączenie materiałów PE oraz PP).

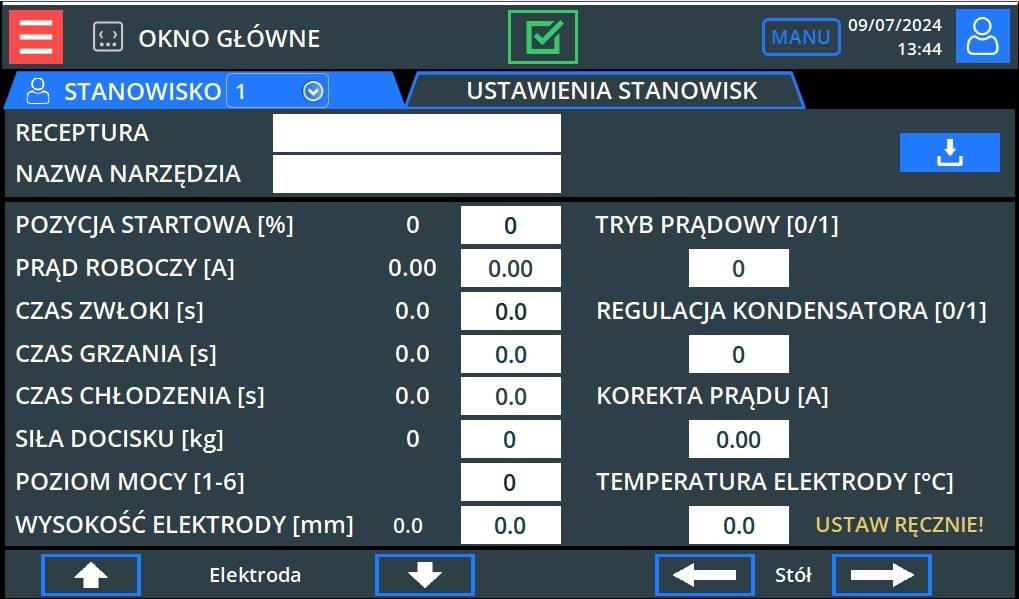

Zaawansowane oprogramowanie i układy elektroniczne między innymi system autotuningu, ATS™ oraz system kontroli zgrzewu WCS™ – kontroluje sterownik PLC zintegrowany z 10” ekranem dotykowym. Nowoczesny i intuicyjny interfejs zapewnia prostotę obsługi, a sam panel zamocowany jest na ruchomym ramieniu i zapewnia łatwy dostęp z trzech stron maszyny.

Bezkompromisowe podejście do bezpieczeństwa operatora podczas pracy realizowane jest przez zastosowanie mechanicznych i elektronicznych zabezpieczeń np. systemu bezpiecznego opuszczania elektrody. Uniwersalna zgrzewarka SIMPLA to maszyna spełniająca wszelkie normy i dyrektywy UE dotyczące bezpieczeństwa pracy. Niezbędne i obowiązkowe pomiary pola elektromagnetycznego mogą być wykonane przez nasze laboratorium pomiarowe Mobilab bezpośrednio po instalacji i uruchomieniu maszyny.

Do maszyny SIMPLA oferowane jest dodatkowe wyposażenie m.in. w postaci składanego stołu zwiększającego powierzchnię roboczą oraz komfort użytkowania.

Możliwe jest wykonanie obowiązkowych w Polsce pomiarów zgodności elektromagnetycznej (EMC) każdej z maszyn przez laboratorium pomiarowe Mobilab działające przy Zemat Technology Group. Laboratorium ma wdrożoną normę ISO/IEC 17025 oraz posiada akredytację nadaną przez PCA (Polskie Centrum Akredytacji) potwierdzającą jakość usług, wiarygodności wyników pomiarów oraz sposobów ich wykonywania.

| Oszczędne generatory wysokiej częstotliwości z mikroprocesorowym sterowaniem moca wyjściową

| Niski pobór mocy oraz rozpoznawanie mocy wyjściowej w czasie rzeczywistym

| Do 90% mniejsze zużycie energii niż w przypadku zgrzewarek stałocieplnych lub impulsowych

| Układ zapewniający precyzyjne dopasowanie impedancji

| Układ automatycznego strojenia (autotuningu) oraz układ zabezpieczający przed przebiciem

| Ultraszybka kontrola mocy odbitej

| Sprawność maszyn na poziomie 70-90%

| Zniekształcenia harmoniczne eliminowane przez filtry pasmowo-pprzepustowe

| Bardzo ograniczone rozpraszanie ciepła, które zapobiega przegrzaniu

Zemat Technology Group Sp. z o.o.

ul. Brukowa 26

91-341 Łódź

Telefon: +48 42 632 84 84

Fax: +48 42 299 60 46