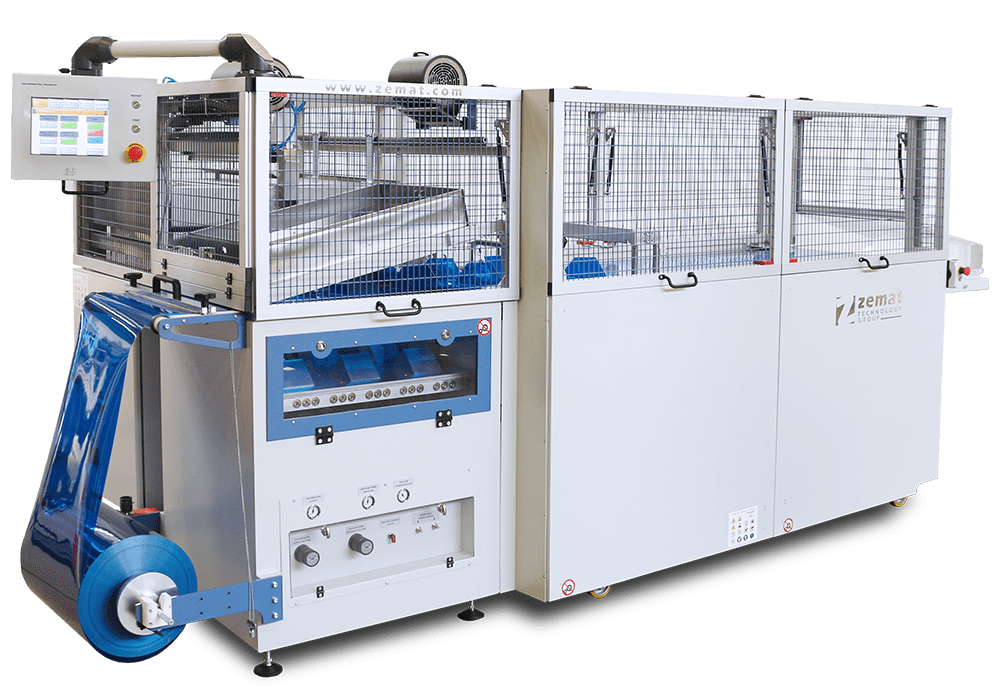

FORMA vacuum forming machines are dependable and easy to use. Forming can be produced efficiently and economically even with small or large batch sizes.

FORMA thermoforming machines produce uniform, high quality plastic packages and articles made from roll-fed thermoplastic materials like OPS, PVC, PET and other thermoformable films.

The PLC controlled automated functions allow for shortest cycles times and optimum contour definition. The robust design of all highly-stressed elements ensures continuous operation with constant availability and long-term production performance. The uniform wall thickness is achieved by the use pre-blowing in positive forming and pre-stretching technology in negative forming. The production process combines the best aspects of both pressure forming and vacuum forming technologies: exceptional precision and speed.

Depending on production demands machines are equipped with special designed finishing modules.

Each thermoforming machine can be equipped with automatic foil feeder which allows usage of heavier foil weight. Especially dedicated to work with FPP and FPN modules.

Get in touch

Zemat Technology Group Sp. z o.o.

ul. Brukowa 26

91-341 Lodz, POLAND

Phone: +48 42 632 84 84

Fax: +48 42 299 60 46

What we do