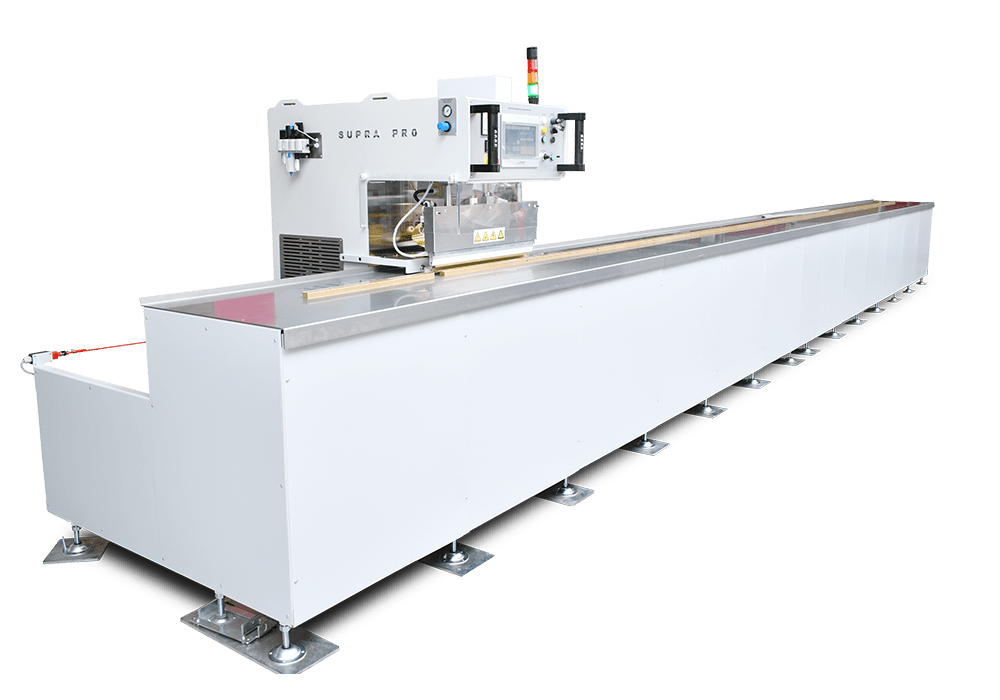

Precyzyjny ruch liniowy głowicy zgrzewającej

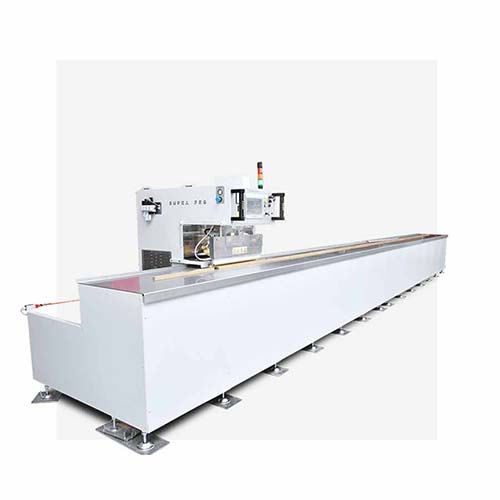

Zgrzewarka wysokiej częstotliwości SUPRA PRO ma uniwersalne zastosowanie zarówno do zgrzewania folii PVC, jak i przygrzewania harpunów do sufitów napinanych przy użyciu specjalnie zaprojektowanego narzędzia IAW ™ „Inverted Airplane Wing”. W opcji dostępny jest próżniowy stół roboczy oraz prowadnice laserowe umożliwiające prace z wąskimi elementami roboczymi i precyzyjne ich pozycjonowanie co usprawnia proces produkcyjny.

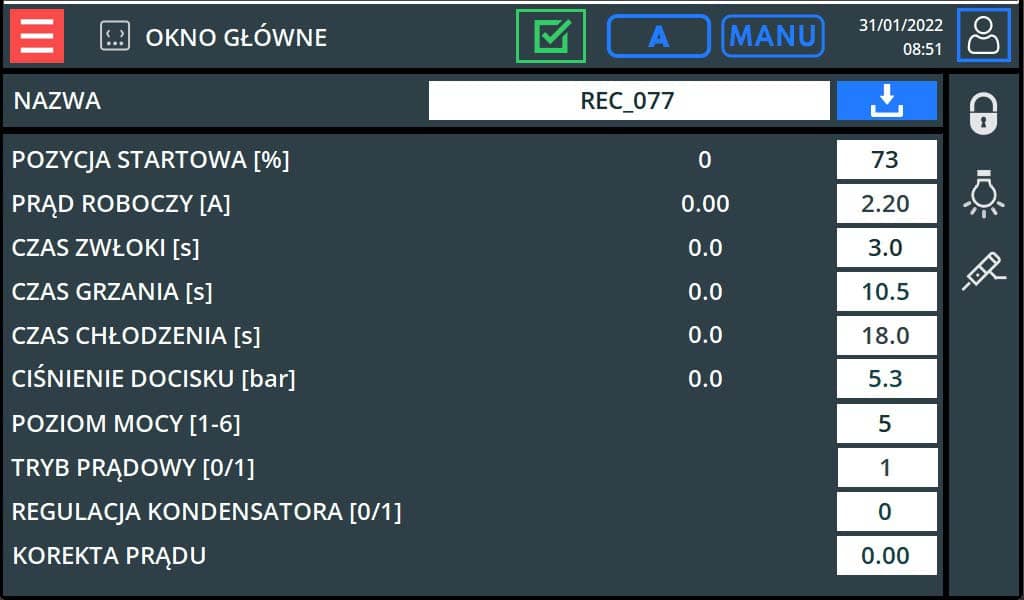

SUPRA PRO posiada moc wyjściową 4 kW oraz wyposażona jest ekran dotykowy. Sterownik PLC kontroluje wiele elementów maszyny między innymi długość ruchu, przebytą odległość czy numer cykli. Głowica zgrzewająca porusza się wzdłuż stołu roboczego na specjalnych szynach, co zapewnia płynny ruch i dokładną kontrolę odległości. Maszyna jest przeznaczona do wielkoformatowych folii PVC, na których wykonuje automatyczne idealnie powtarzalne cykliczne zgrzewy.

Maszynę można zmodyfikować i przekształcić w standardową zgrzewarkę liniową, co umożliwia produkcję np. banerów reklamowych lub plandek samochodowych.